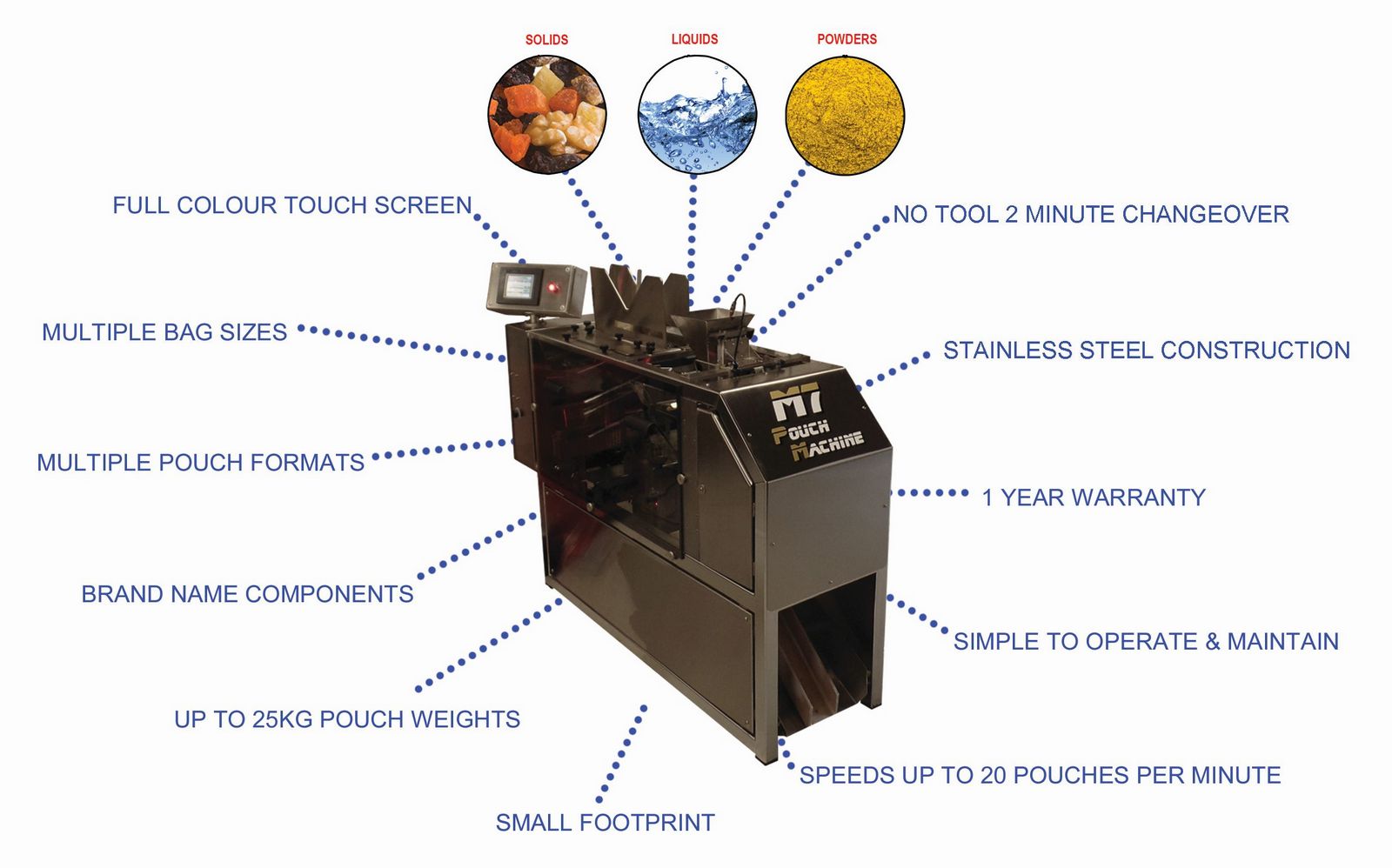

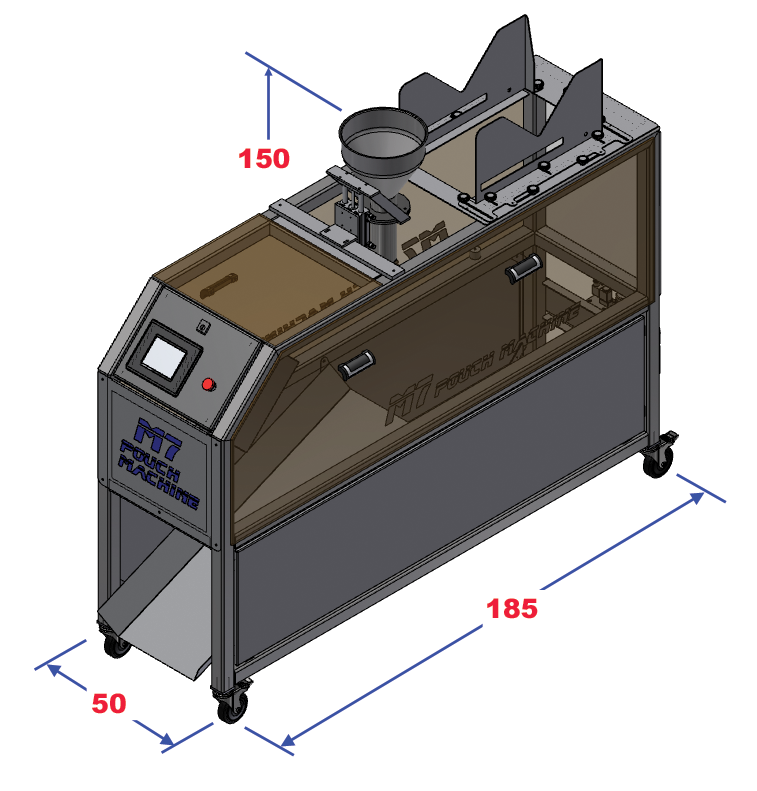

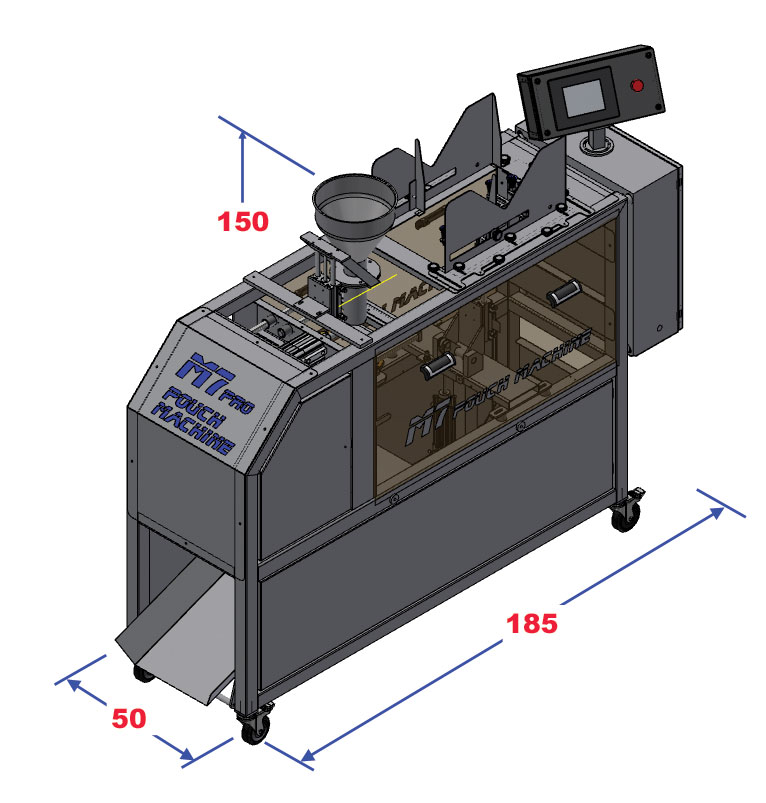

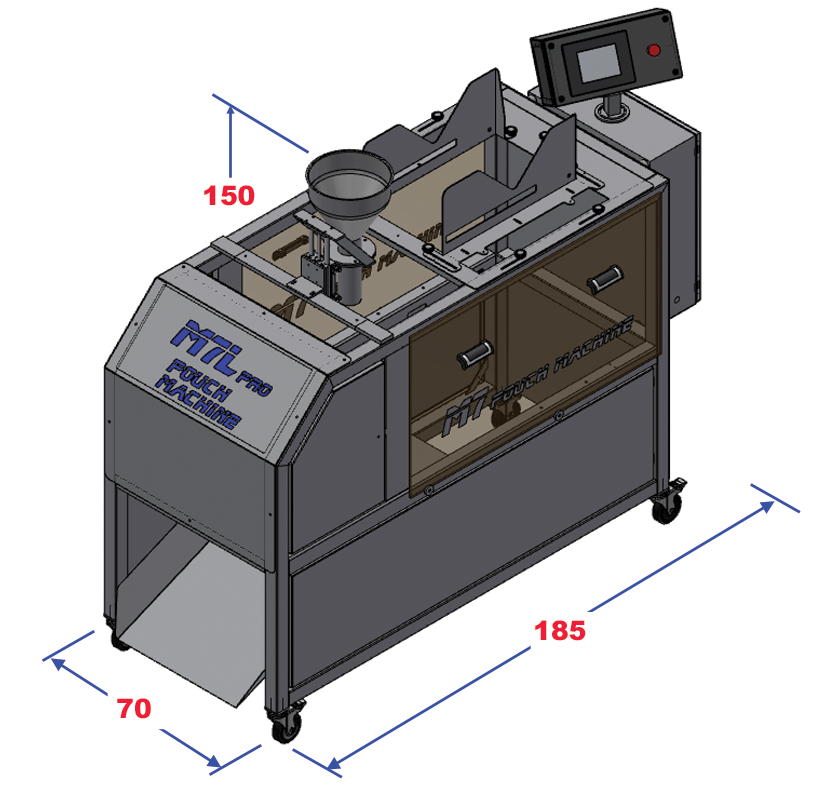

With our M7 as the flagship and 15 years of ingenuity in multiple markets, the M7 has evolved to meet our customer's needs of "low maintenance" and "maximum up time". Our line of pouch machines allow you to move away from costly, labor-intensive manual packing to a world of affordable high-speed automation. Capable of interfacing with a multitude of fillers and designed to be simple to use with a small footprint.

Allows Low Pressure washdown - No Harsh Chemicals

Supports heavy bag filling of products weighing more than 2kg - Also support setting

Allows M7 to package side gusset and quad seal pouches

Opens Zippers that come closed from manufacturer

Moves CIJ Print Head across the bottom of the magazine - Works with most brands

Bounces the full pouch after filling to keep "fill level" below seal area

Allows variuos types of corner spout pouches to be run

Machine parts manufactured from 316 Stainless Steel

Thermal embossing in the seal area. Available in 3,4,5, 6mm sizes up to 20 digits

Removes excess air from pouch. Note Soft Vacuum will not remove ALL air

Encapsulates pouch around filling tube to eleimante dusct - includes dust extraction pounts

Custom designed to suit spefific scoops - one per pouch

ALternative sealing method commonly used for liquids and retort

Used to take oxygen levels in the pouch down to 0.5% to 5% dependant on product and set up

Product is weighed in pouch as its filled from an Auger.

Sends product to 2 heads from a single source.

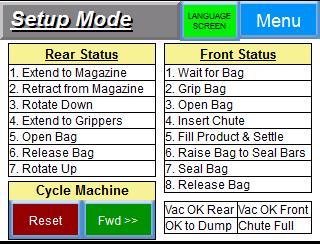

With our Touch Screen, set up, operation and troubleshooting are as easy as using your smart phone. Think of it as having a factory trained technician at your disposal, it is always monitoring & fine tuning for you. Since staff responsibilities differ it includes 3 levels of password security.

The individual QR is personalized for each

installation. Ideal for maintenance and retraining personnel, it includes:

Digital manual

Parts Listing

How To Videos

Troubleshooting

Parts ordering

Contact Numbers

Have Multiple jobs to run? No

problem store each one for

easy recall and fast changeover